Where ships go to die

Gie Goris and Nicola Mulinaris, winner of Public Eye's Investigation Award

Decommissioned deep-sea vessels are floating toxic waste. Their disposal is laborious and costly, and regarded as a menace by those who want to protect both the workers and the environment. The more unscrupulous companies have their ships scrapped on South Asian beaches, where they poison the waters and endanger the wreckers. Swiss companies are among those who save a lot of money in the process.

The investigation context explained in less than 3 minutes, by the authors Gie Goris and Nicola Mulinaris

The investigation context explained in less than 3 minutes, by the authors Gie Goris and Nicola Mulinaris

The road to Alang is lined with shops and warehouses selling items that cossme from ships that used to sail across oceans: oak desks, faux crystal chandeliers, life vests and lifeboats, ropes, electric cables and switches, leather chairs, paintings, giant generators and motors – just about anything you can name. This is ship recycling in its most literal sense, even though these commodities are in reality no more than surplus products. The real reasons why huge ships end up on the beaches of Alang are their steel hulls and frames. Steel is where the real profits are to be made.

Alang and neighbouring Sosiya used to be simple fishing villages on India’s north-western coast. Today, they are famous – or rather infamous – because shipbreaking yards are now taking up kilometers of beaches along the Gulf of Khambhat, where the Arabian Sea cuts deep into the state of Gujarat. These shores have thus become boat cemeteries.

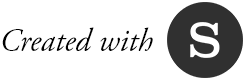

A few days before we arrived in Alang, in early September 2018, two men died while working at the RKB Group-owned Honey Ship Breaking yard. Bhuddabhai Kudesha from Alang, and Ali Ahmed from Jharkhand, fell victim to an industry often seen as providing “the most dangerous jobs in the world”. The same yard was used less than a year ago by the Swiss company MSC to break up the MSC Alice. You can read more on this story below.

Bhuddabhai’s last day

Bhuddabhai was 33. On August 31 2018, as on every other working day, he woke up around six in the morning, when the first light penetrates the darkness and ends the silence in his village. His eight-year-old son and two daughters, aged six and four, were still sleeping, but his wife was already up and preparing their breakfast. Six years ago, Bhuddabhai had managed to get a job on the shipbreaking yards of Alang, situated about three kilometers from their house.

He knew how rare it was for a Kholi – originally a fisherman’s caste but now mostly day laborers in seasonal agriculture – to find work in that industry.

On the morning of the accident, Bhuddabhai was busy removing toilets from the MV Ocean Gala. His employer would later sell these items to the second-hand shops that line the road to Alang. It wasn't a particularly well-paid job, but it certainly made a better living than the farm work his father and younger brother Rajabhai did. Bhuddabhai would often lend them a helping hand on Sundays or before he left for the yards on his Honda motorcycle at 7.30 in the morning. On that day, Bhuddabhai took, for the last time, the dusty road from his home to the Honey Ship Breaking Yard.

Dhammabhai Kudesha, Bhuddabhajs father

Dhammabhai Kudesha, Bhuddabhajs father

We visited Alang only a few days later, and the exact circumstances of the accident were still murky when we spoke to his family. What transpires is that a piece of the hull must have broken off unexpectedly, taking Bhuddabhai with it as well as Ali Ahmed, the gas cutter who was cutting through the steel on the ship's ninth floor to create an extra exit. None of the workers were wearing safety belts. Nor were they required to, according to the shipyard’s owner. They were working inside the ship; only the cutters working on the ship’s exterior must wear safety belts.

Workers’ rights? Non-existant!

An endless list of problems

To better understand the conditions under which breakers work in Alang, we met Vidyadhar Rane, who is secretary-general of the union trying to organise workers there. In addition to the safety problems on the sites, there are many essential points that should be improved or obtained:

“Housing. Toilets. Canteens. Correctly paid overtime. Paid holidays. Health and accident insurance for everyone.Adequate hospital capacity.”

The latter can make the difference between life and death when disaster strikes. When Bhuabhai had the accident at Honey Ship Breaking Yard, he was brought to the public hospital in Bhavnagar, a provincial town more than 50 kilometers from Alang. It takes more than an hour to cover that distance on the narrow two-lane road, full of speed bumps, stray cows, trucks and dangerous traffic. There is a small, 10-bed clinic run by the Indian Red Cross and the Alang Hospital, which has 20 beds, but these do not have the equipment to deal with serious injuries. These infrastructures are completely insufficient to meet the needs of almost 160 yards in Alang, on which 15,000 to 30,000 workers dismantle huge ships under extreme conditions, risking their lives. The numbers given vary with each interview, and official statistics are not available, since most labour is informal anyway.

“There is no union in Alang,” affirms Nikhil Gupta, co-owner of Rudra Green Ship Recycling, one of the “better” shipbreaking yards in Alang. “And that makes doing business in Gujarat so nice; we have no unions because everyone is on the same page.” Gupta makes this surprising – and patently untrue – statement at the end of an interview during which he has tried to explain the economic laws of demand and supply that govern the world of globalised shipping and shipbreaking, or as industry captains like him prefer to call it: “recycling”. Although the other yard owners we speak to aren’t as disparaging, no-one has anything resembling a formal relation with a union. Nor do they engage in collective bargaining at company or sectoral level. “When there are problems, we deal with the workers directly. Much faster that way” says Nitin Kanakiya, the secretary of the Ship Recycling Industry Association (SRIA) and the owner of Triveni Yard, in Alang.

A billion-rupee industry

Dr Sahu Geetanjoy, a researcher at the Tata Institute for Social Studies in Mumbai.

“The laws to protect workers are insufficient and are not enforced,” explains Dr Sahu Geetanjoy, a researcher at the Tata Institute for Social Studies in Mumbai, and one of just a few academics studying labour conditions in the shipbreaking industry. The government’s own financial interests may explain its lack of commitment to enforcing labour and environmental rules, he says. Through taxes and the leasing of land on the beaches, the shipbreaking industry contributes around 7 billion rupees, or about €87.5 million, to the Gujarat state coffers per year.

When we asked Bhuddabhai’s family what they expect from the owner of the shipbreaking yard, the answer came instantly: “Nothing.”

Their answer reflects centuries of humiliation and marginalization; Kholis have never been able to expect anything from the wealthy or the upper castes. Bhuddabhai’s brother and nephew still don’t know whether the family will receive any compensation. Raj Bansal, the Honey Ship Breaking Yard owner, promises that the family will receive about €6,250, an amount that corresponds to three years of work on the yard. But a pension for the widow, Bansal says, is not an option. Added to the immense pain of having lost her husband and the father of her three children is the destitution, more desperate than anything she has known so far.

Bhuddabhai's tragic story evokes the threat to the lives of so many others; tens of thousands of men who, to support themselves and their families, dismantle ships with their bare hands on the beaches of South Asia.

According to data published by the Brussels-based international NGO Shipbreaking Platform, every year around 1000 ships are scrapped, and 65 to 75 percent of them end up on one of the three breaking beaches in India, Pakistan and Bangladesh.

Once a ship is destined for dismantling, it is considered to be hazardous waste under international law, specifically the 1989 Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal.

One of the most dangerous jobs in the world

In 2015, the International Labour Organisation (ILO) warned about the dreadful consequences of this practice: “Shipbreaking has grown into a major occupational and environmental health problem. It is amongst the most dangerous of occupations, with unacceptably high levels of fatalities, injuries and work-related diseases.”

In India, data from the Gujarat Industrial Safety and Health Department show that at least 470 fatal accidents occurred in Alang between 1983, the start of the local shipbreaking industry, and 2013, indicates Dr Geetanjoy of the Tata Institute for Social Studies. “There is no central and reliable register of accidents in the yards,” he explains. But according to the Indian Supreme Court, the incidence of fatal accidents in shipbreaking (two in every 1000 workers) is higher than that in mining (0.34 per 1,000 workers), which is nevertheless considered to be “the most accident-prone industry.”

Dr Sahu Geetanjoy, a researcher at the Tata Institute for Social Studies in Mumbai.

Dr Sahu Geetanjoy, a researcher at the Tata Institute for Social Studies in Mumbai.

Externalised costs

In 2009, the UN Special Rapporteur on toxic wastes already described in a report the long-term risks of shipbreaking, a time-bomb: “In shipbreaking yards, workers are often exposed to toxic chemicals including asbestos dust and fibres, highly toxic industrial chemicals which have been banned for decades but are still present in ships, as well as lead, mercury, arsenic or cadmium in paints, coatings and electrical equipment. Workers are often without protective equipment that reduces exposure. Prolonged exposure to these chemicals increases the risk of developing slow-progressing but fatal diseases, which may not become apparent until many years after exposure.”

As in other sensitive sectors, the human and environmental costs of such practices are paid by poor countries. The current Special Rapporteur, Baskut Tuncak, is more explicit about the responsibility of the shipping industry, “which externalises impacts on poor workers and communities in developing countries”.

In that sense, container ships and other vessels are, right to the end, sad symbols of the abuses of globalization.

- BACKGROUND -

Weakening and circumventing laws

The United Nations Environmental Program (UNEP) adopted the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal in 1992 following numerous hazardous waste trafficking scandals in the late 1980s. The Basel Convention, which has been transposed into EU law by the EU Waste Shipment Regulation, controls the international trade of hazardous waste. It’s relevant to ship dismantling because a ship, which usually contains hazardous materials within its structure, is considered hazardous waste when destined for breaking. The Basel Convention, ratified by 187 countries, remains the only international legislation in force that aims at protecting developing countries from the dumping of toxic ships.

However, the shipping industry has exploited loopholes in the Basel Convention and opted for the more profitable breaking of ships on South Asian beaches. Due to the fact that a vessel becomes waste only when the intent to dispose of it is evident, to escape the Basel legislation it’s sufficient for ship owners to hide their true intentions from the authorities of the exporting state – i.e. the state from which the vessel leaves for its final voyage to the scrapyard.

When the Basel Convention State Parties started discussing more effective ways of regulating the trade of toxic ships – such as pinpointing the responsibility of countries where ship owners are headquartered – the United Nations’ specialized agency, the International Maritime Organization (IMO), decided to start working on a new legally binding convention specifically for ship recycling to be based instead on enforcement by the flag states. The resulting Hong Kong Convention (HKC) on the Safe and Environmentally Sound Recycling of Ships is not expected to come into force before many years, since, to date, it has been ratified only by six countries. Civil society has been joined by the UN Special Rapporteur on Human Rights and Toxics, European policy makers and developing countries in denouncing the HKC for setting low standards that would rubber-stamp current dirty and dangerous practices on South Asian beaches.

At the European level, due to the ease with which ship owners have been circumventing existing waste laws, a new regulation on ship recycling has been adopted. From 31 December 2018, EU-flagged vessels can only be recycled in facilities compliant with the regulation’s requirements and included in the European List of ship recycling facilities. The EU regulation sets higher standards than the HKC: the beaching method is not allowed, and requirements related to downstream toxic-waste management, as well as labour rights, are included.

Hypocritical Europe

Ecological disaster and the “gravity method”

The environmental consequences are also dramatic. In June 2016, the EU Directorate-General for the Environment published an overview of several studies, one of which clearly showed just how heavily the Alang–Sosiya natural environment has been polluted by copper, cobalt, manganese, lead, cadmium, nickel, zinc and mercury.

The Commission also refers to a previous study, published in 2001, that found that mercury levels in Alang were 15,500 percent higher than at a control site, and 16,973 percent higher for petroleum hydrocarbons. The researchers also detected the presence of certain bacteria at high levels.

Some of the pollution is directly related to what the shipbreaking industry calls the “gravity method”: this is when large parts of the ship are cut with a blowtorch and crash down on the beach.

The incredible impact of falling tonnes of steel combined with the process of cutting steel using very high-temperature gas flames causes often-toxic paints to be released into the sea and soil.

The ships are broken during low tide and all the oil residues, heavy metals and toxic substances that aren’t cleaned up before high-tide are spread across the entire marine environment.

“Europe is hypocritical”

However, all the site owners we interviewed have a common refrain: “Alang’s yards are well on track to becoming green, but the European companies lack serious commitment to the cause they preach.” Nithin Kanakiya, owner of Triveni ship recycling yard in Alang and the secretary of the local Ship Recycling Industry Association (SRIA), is even louder and clearer.

“Europe is hypocritical. From one side, it demands the impossible in terms of salaries, insurances, safety and environmental protection, while from the other side their only interest is profit maximisation, for which they are prepared to play one breakers yard against the other,” he insists.

We asked Komalkant Sharma, the owner of the Leela Group of Companies, whether he looks at the big shippers for support: “When we find that ship owners are only interested in top dollars, then it becomes impossible for us to continue doing business with them. Leela aims to be better than the others in social and ecological terms, but that does not come for free. And that is why European ship owners should bear their share of responsibility and encourage the necessary investments by accepting lower prices for their vessels, or by engaging in the longer term with recycling companies. But the ship owners dump the responsibility on the recyclers.”

If Leela is considered to be one of the “best” yards in Alang, then it’s good to remember that Ravindra Chaudhari died there on Sunday, April 15 2018, while doing maintenance work. A sheet of steel, which was half cut out of the hull of the vessel Pata Glory, fell down, as described by the Times of India.

Landlocked Switzerland

A hell for (mostly) internal migrants

Many vessels are dismantled in Chittagong, Bangladesh, where labour and environmental conditions are even worse than at Alang. Mohamed Ali Shahin, who works for Young People in Action (YPSA) and is deeply involved in the shipbreaking issue, told us on the phone that on 10 November a worker at the SH Enterprise yard died while breaking the Ukraine-owned MV Velda. And that the day before another worker died while disassembling the Indian-owned Peri at the Golden Iron Works yard. Earlier this year, two workers died on the Zuma Enterprise yard; they were working on the MT EKTA, an oil tanker that, according to shipping databases, was sold to the breaker by the Swiss shipping company Navimar. Navimar bought the vessel that was operated by Maran Tankers, a subsidiary of Greek Anangel Shipping Group, in September 2017, only a month before it was brought to the beach at Chittagong, so it’s clear that the Swiss company acted as a conduit to scrap the ship, making a purely financial transaction.

“Zuma Enterprise is one of the worst yards in Chittagong,” says Ali Shahin. “It has no safety measures, no compliance with international environmental standards, and no waste management.

Why would a Swiss company choose such an unsafe yard to cooperate with?”

Zuma is not only unsafe, it’s also cheap with regard to workers’ health. “Their practice,” adds Shahin, “is to pay the family of a worker who died in an accident the legal minimum of 100.000 taka (a little over 1000 euros). But other yards would compensate such a tragic loss with 500.000 taka.”

- BACKGROUND -

The business model of “flag swapping”

To maximize profits, avoid responsibility, and exploit loopholes in international legislation, the shipping industry has recourse to so-called “flags of convenience” (FOC): ship owners can register their vessels under the flags of countries which have nothing to do with them or their companies. Many countries offer this kind of low-cost registration with little regulatory control and reduced tax rates. As a consequence, the FOC phenomenon has created a system whereby states compete for the ships with policies that promise lower costs and lower wages for seafarers, and by keeping taxes, fees, and regulatory burdens light.

Whereas around 75% of all ships already register under FOCs during operational use, even more ships flag out of responsible registries, including European ones, as they get older. This strategy is often used for their last voyage to the breaking yards. Ship owners opt for end-of-life FOCs that offer special last-voyage discounts with little control, such as the registries of Tuvalu, Comoros, Palau or St Kitts and Nevis – flags that are hardly used while vessels transport goods. These flags have a track-record of poorly implementing and enforcing international legislation.

Attempts to regulate ship-recycling practices without obligations for ship owners beyond flag-state jurisdiction will fail, as re-flagging to a non-party or non-compliant end-of-life flag, or selling the vessel to a cash buyer – who can do the same – remains an attractive solution when seeking to avoid stricter rules. Hazardous waste usually follows the path of least resistance, and backed by FOCs ship owners are able to continue choosing profits at the cost of people and the environment.

19 fatalities in 2018 – a sad new record

The government should do more to make it cleaner and safer, he argues, but it’s not just a Bengali responsibility. As he emphasises: “European shipowners could do so much more to demand and stimulate safe and clean shipbreaking. They can enforce European standards and should invest, for instance, in waste-collection facilities. And, of course, they could start with cleaning out their ships of all the toxic materials before they even send them to South Asia.”

As in Alang, many of the shipbreaking workers in Chittagong are internal migrants who live in unsanitary accommodation. They work long hours, usually without labour contracts, and can take no holidays. The shipbreaking yards prevent trade unions from organising the workers. In Chittagong, at least 15 workers were killed in 2017, while at least 22 suffered severe injuries.

Provisional figures for 2018 indicate that 19 workers have lost their lives, the highest number in the past nine years. The majority of the deaths are caused by fires, falls from great heights, and workers being crushed by ship parts that come loose.

Switzerland is a global dumper too

Although it has no access to the sea, Switzerland is home to big companies specialising in maritime chartering. Whereas Mediterranean Shipping Co. (MSC) is well known among cruise lovers, most people have never heard of the other shipping companies, most of which are domiciled on the shores of Lake Geneva. Even less well known is the sad fact that the Swiss shipping sector also has a poor track record regarding the dismantling business in South Asia.

According to our calculations, based on a variety of industry sources, ninety Swiss-owned vessels ended up on beaches in Bangladesh, India and Pakistan between 2009 and today.

The names of the companies involved are on the record, but receive little publicity: Atlanship S.A., Doris Maritime Services S.A., FleetPro Passenger Ship Management AG, Lumar S.A., MSC Mediterranean Shipping Co., Sallaum Group SA, Shipfin S.A., Sider Navi S.p.A., and Taunus Shipping S.A.

According to the UN Conference for Trade and Development (UNCTAD), Switzerland ranks 20th in the world in terms of the number of ships owned. However, the NGO Shipbreaking Platform reports that, in terms of the number of ships scrapped on South Asian beaches, Switzerland rises in the ranking. Almost all Swiss ships end their working days in such conditions, making Switzerland one of the biggest polluters in terms of the irresponsible management of its old ships.

MSC beaching champion

MSC does not walk its talk

Of the 90 Swiss-owned vessels scrapped on South Asian beaches in the last ten years, a stunning 80 belonged to MSC, the second-biggest container shipping company in the world. This giant with a turnover of 27 billion euros in 2017 does not have to publish its numbers, since it’s a family owned and run company, headed by its Italian co-founder Gianluigi Aponte. In 2009, he received the Neapolitan Excellence of the World award from the then Prime Minister Silvio Berlusconi, and in 2013, the Cavaliere del Lavoro (Knight of Labour) honorary title from the President of the Republic, Giorgio Napolitano. To be considered for the title, candidates must have an impeccable record of civil and social accomplishments, and have abided by all tax laws, while paying particular attention to workers’ protection and assistance. More recently, in October 2018, MSC won the Greenest Ship Owner of the Year award at the annual Green Shipping Summit in Amsterdam. “MSC was commended for its efforts to promote the sustainable use of marine resources and investments in green technologies,” the company writes on its website.

A shipping company that, to quote their Chief Sustainability Officer, aims “to become the most sustainable, technologically advanced and customer-focused shipping line in the industry” while at the same time sending its decommissioned vessels to South Asian beaches, has some explaining to do. We therefore contacted MSC two weeks after they were honored with the Greenest Ship Owner Award 2018 and told them that we wished “to get the facts and numbers about ships sold for breaking/recycling and to understand the decision processes or criteria used by MSC.” The response from Geneva was brief: “Thank you for your interest in MSC’s environmental strategy. As of today, we decline to take part in your research.”

Inexistent standard

In MSC’s sustainability report there is only one reference to the issue: “Our ship recycling practice is another important area of emphasis for MSC, as it is strictly related to labour standards, environmental protection and human rights […] only recycling yards with IMO HKC standards (see box 3) , ISO 14001 (environment), ISO 30001 (recycling management) and OSHAS 18001 (health & safety) standards are selected for recycling at the end of the useful life of a ship.” It’s remarkable that MSC refers to ISO 30001 as one of the conditions for working with shipbreaking yards, as this ISO standard number does not actually exist! Or perhaps it’s symptomatic of the whole sustainability of its shipbreaking practice: big declarations, but no results?

We wanted to know specifically whether MSC could confirm that all these requirements are fulfilled by the yards in Alang used by that company. For a company that prides itself on its corporate social responsibility, the response was again disappointing: “We hereby confirm that we are not able to satisfy your request.”

Poor track record in Alang

The beach at Alang is where the business practices of MSC and the destiny of Bhuddabhai converge, although with a time lag. On 4 August 2009, the MSC Jessica caught fire while it was being disassembled on a beach in Alang, resulting in the deaths of six workers. In 2017, not even a year before Bhuddabhai’s accident, the MSC Alice was scrapped at the Honey Ship Breaking yard in Alang.

Although its certifications suggest that the yard is one of the better ones in Alang, the accident on 31 August 2018, in which two workers died while dismantling a cruise ship, shows that such privately issued certificates claiming compliance with the weak standards of the Hong Kong Convention fail to combat even the worst dangers of shipbreaking.

Public Eye's Investigation Award

Shedding light on hidden facts can change the world: this strong belief led Public Eye to set up the Investigation Award on the occasion of its 50th birthday to support the work of journalists or NGOs that investigate the practices of companies and their harmful ramifications on developing or emerging countries.

A prestigious jury selected two projects from 55 proposals submitted from over 20 countries. They received crowdfunding – over 300 people contributed to our participative funding-raising campaign. They allowed Nicola Mulinaris, from the NGO Shipbreaking Platform and Gie Goris of MO* magazine (Belgium), to carry out this investigation, and enabled Marie Maurisse to reveal the secret recipes of Swiss cigarette companies. A big thanks to them!

Although it focuses on present action, the Investigation Award was set up to celebrate Public Eye’s anniversary and reflects the organisation’s long tradition of investigative journalism; Public Eye has always associated its advocacy and campaigning with the often arduous process of shedding light on illegitimate or illegal activities against which action must be taken.

Focus on Global Justices

Public Eye fights against injustice that has a significant link to Switzerland and calls for human rights to be respected around the world. Through our research, advocacy and campaigning, we express the voice of close to 25,000 members in calling for Switzerland to act responsibly.

Support us at Public Eye by making a donation!

Investigation: Gie Goris (MO* magazine) und Nicola Mulinaris (NGO Shipbreaking Platform)

Edition: John Durham

Photos: Tomaso Clavarino, Amit Dave, Studio Fasching, Pradeep Shukla, GMB Akash/Panos, Shiho Fukada/Panos, Brendan Corr/Panos, Gie Goris

Web-design: Melanie Nobs, Public Eye